Table of Contents

New design

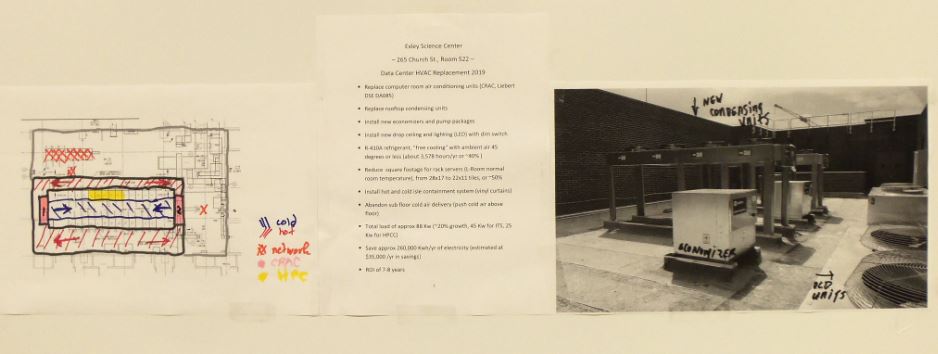

Exley Science Center – 265 Church St. – Data Center HVAC Replacement

Replace computer room air conditioning units, replace rooftop condensing units, install new economizer and pump package, install new drop ceiling and lighting, install hot and cold isle containment system. New system will replace a ~40-year-old system that is critical for the campus IT infrastructure.

- Project Schedule: 5/28/19 – 10/1/2019

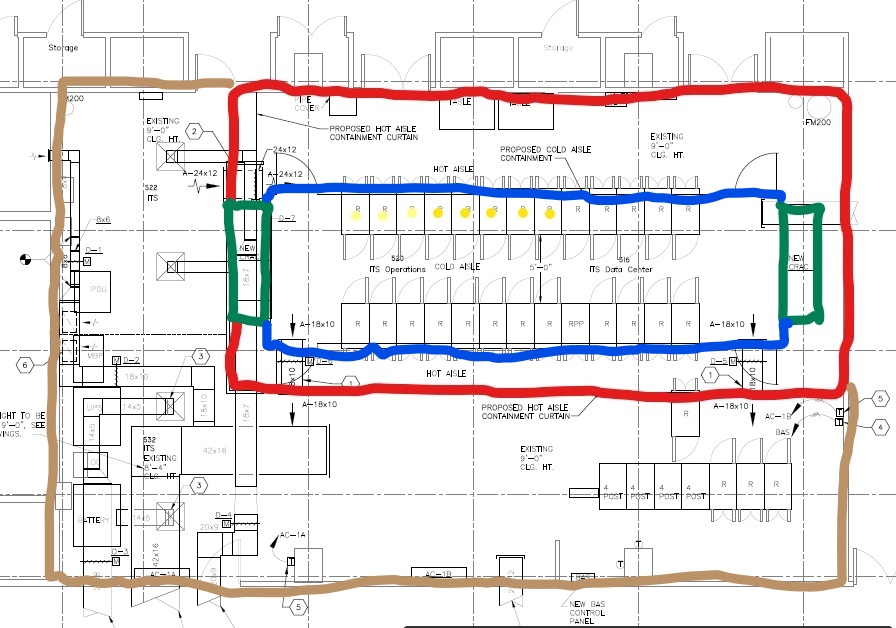

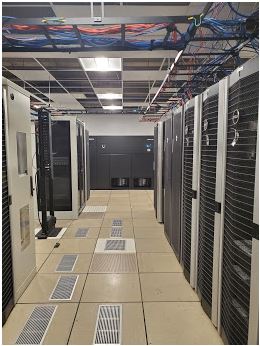

Our new data center upgrade summer-fall 2019. New LED lights, new ceiling. Because of virtualization we are reducing our cooling square footage. Using vinyl curtains we'll create a cold aisle (blue). Two new Liebert CRAC units (green) will discharge cold air above floor into this cold aisle. Two rows of 13 racks with servers will pull cold air and discharge into hot aisles (red). CRAC unit intake of hot air is from top. We are abandoning delivering cold air from below floor. (Raised floor only 7 inches high with all kinds of crap in there, cables, pipes, etc). Coolant gas will bypass chillers on roof if outdoor temp is 45 degrees or less generating significant savings (economizers). The rest of the room will be normal room temperature, we call this the L-Room (brown). Automatic control dampers will supply the L-Room with some cold air to maintain network equipment.

The HPCC is in the top row of racks on the left (room for 3 additional racks, light yellow dots, 5 existing racks, dark yellow dots).

Summary Bullets

⦁ Replace computer room air conditioning units (CRAC, Liebert DSE DA085)

⦁ Replace rooftop condensing units

⦁ Install new economizers and pump packages

⦁ Install new drop ceiling and lighting (LED) with dim switch

⦁ R-410A refrigerant, “free cooling” with ambient air 45 degrees or less (about 3,578 hours/yr or ~40% )

⦁ Reduce square footage for rack servers (L-Room normal room temperature), from 28×17 to 22×11 tiles, or ~50%

⦁ Install hot and cold isle containment system (vinyl curtains)

⦁ Abandon sub floor cold air delivery (push cold air above floor)

⦁ Total load of approx 88 Kw (~20% growth, 45 Kw for ITS, 25 Kw for HPCC)

⦁ Save approx 260,000 Kwh/yr of electricity (estimated at $35,000 /yr in savings)

⦁ ROI of 7-8 years

Vertiv Free Cooling Calculator 80 degree return air (conservative) with 70% load rates full free cooling hours are at 44% for Bridgeport and 48% for Hartford. So the expected 40% lsted aboveis low water mark as that percentage goes up if return air gets hotter. At 85 degree it yields between 53-56%.

Tech Summary

You don't get approval for a roughly $250K project without some serious reasons and numbers. To start with an air flow dynamics analysis, and attempted improvements, utterly failed to improve our data center's environment. With the help of FEACE we next embarked measuring our power consumption and cooling needs. The proposed solution is described above. The significant improvements are; abandon subfloor cold air delivery, reduce square footage cooled, free cooling below 45 degree ambient air, and much more energy efficient cooling units.

There are two sources of power and most racks (other than HPCC) are tied into both. Emergency power that comes from the enterprise UPS (with bypass to utility power and backed by gas generator) and plain utility power delivered directly from the power grid. The UPS logs kwh consumed. The utility panels were clamped for a month and consumption logged. The HPCC racks were individually logged using an PDU with amp meter. Since the HPCC is a big variable much effort was spend to assess it's consumption, read the HPC Power page.

| Excley Data Center Loads | total kW |

|---|---|

| Emergency power backed racks (x2) | 43.5 |

| HPC Racks | 22 (Peak) |

| Storage (rstore) | 2 |

| GPU expansion | 7 |

| Sub Total | 74.5 kW |

| Expansion Capacity - up to 25% of current load | 18 |

| Sub Total | 92.5 kW |

| Lighting load and building envelope losses | 2 |

| Total Data Center Cooling Load | 94.5 kW |

| Miscellaneous Load - UPS Lossess | 5 |

The total cooling load for the data center space including load values above, and a potential for a 25% capacity increase is approximately – 94.5 kW. The 5 kW load associated with heat loss from the UPS is not factored into the data center cooing load and is planned to be handled separately.

It is recommended for the purpose of the study to use a total load of approximately 88kw, based on the capacity of the proposed cooling units. That would account for enough capacity to handle today's load and associated equipment losses with room to grow by approximately 18%. The cooling installed would also have the ability to be expandable if additional growth is required beyond the 88 kW design limit. The breakdown of the proposed load is as follows:

| Proposed Excley Data Center Loads | total kW |

|---|---|

| Emergency power backed racks (x2) | 43.5 |

| HPC Racks | 22 (Peak) |

| Storage (rstore) | 2 |

| GPU expansion | 7 |

| Sub Total | 74.5 kW |

| Expansion Capacity - up to 18% of current load | 13 |

| Sub Total | 87.5 kW |

| Lighting load and building envelope losses | 2 |

| Total Data Center Cooling Load | 89.5 kW |

| Miscellaneous Load - UPS Lossess | 5 |

June Meetings

6/24

I will be updating you weekly on the progress in the data center. PP and vendors/contractors are meeting weekly (at 7:30am) to discuss past and upcoming week work items. Attached the preliminary schedule. End date Sept 30, hopefully.

Ceiling has been removed. Internal wall demolition to finish by Thu 6/27. ACC2 (roof chiller) removed, internal piping removed, new piping 70% complete for first new unit (we are running on two cooling units, set points lowered to 71 degrees). Very little dust, yea! CRAC2 (cooling tower in DC) to be demolished next.

Discovered non functioning humidifier, mobile wall track and steam/condensate piping end points behind ceiling. First two not expected, will be removed. Latter will be removed but may need a building wide shutdown of steam/condensate (planned for Tue 7/2 if no work around can be found). Will be announced.

Fire suppression system will be shutdown for modifications next week. Temporary fire/smoke system will be put in place. A floor tile vendor was found in case we need new ones.

June Photos

The high quality pictures in this batch are made by Physical Plant!

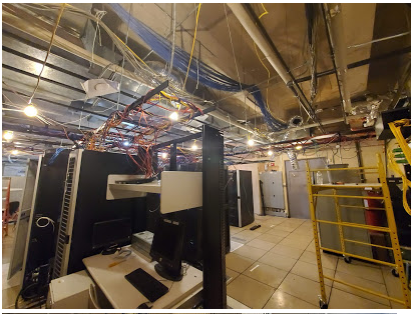

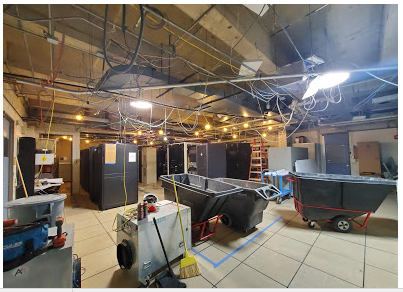

Before, L-room

Before, L-room

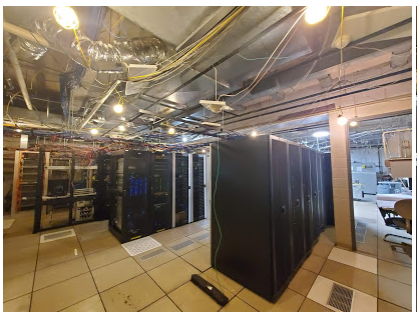

Before, entire room

Before, entire room

Before, CRAC1

Before, CRAC1

General Contractor

General Contractor

L-Room, network area

L-Room, network area

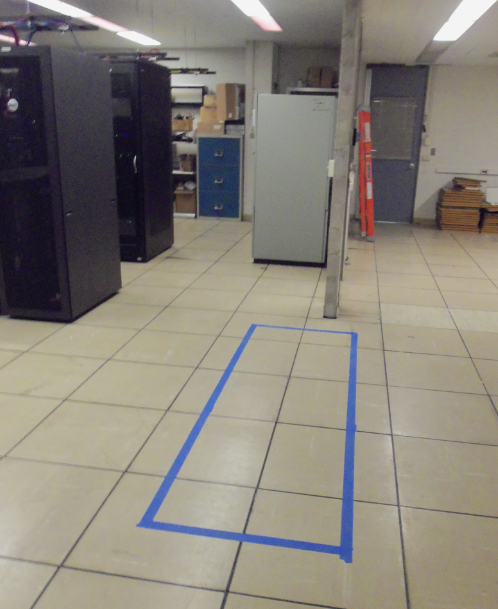

5-6' wide cold aisle

5-6' wide cold aisle

New & old CRAC2, wall

New & old CRAC2, wall

CRAC2 chiller removed

CRAC2 chiller removed

Wall demolition

Wall demolition

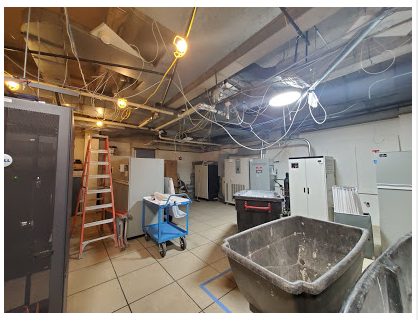

Wall gone, ceiling gone

Wall gone, ceiling gone

Ceiling/Lights removed

Ceiling/Lights removed

Porch party lights up

Porch party lights up

Cool Shirts

Cool Shirts

KVM station

KVM station

New CRAC at rigger

New CRAC at rigger

View from CRAC1

View from CRAC1

Cleaned ceiling

Cleaned ceiling

L-Room, UPS area

L-Room, UPS area

July Meetings

7/2

Rest of this week is devoted to removing old non-functioning, moldy, ductwork.

Old ductwork will be capped at door.

Continue refrigerant piping, electrical and insulation for CRAC2 unit.

CRAC units have arrived at rigger.

Next week new ceiling and lights will go up.

Fire suppression reconfiguration today.

Sidebar: Bill N. informs me Two L2 EV charges will be installed in L Lot of Lawn&Church serving 4 parking slots (like Freeman). Three L2 EV charges will be installed serving 6 parking slots this fall at Films Studio when construction fence is moved back.

7/9

Random safety inspections, all passed.

Duct demo complete.

Grid is going up (to hold new ceiling tiles)

Crac2 demo this week.

Roof units to arrive 7/31 (Excley loading dock closure, announcement will confirm)

7/16

Two ductless AC units installed on wall.

Ceiling grid 95% done.

Asbestos found in mastic on humidifier,

cut around seam and bag.

Rigger confirmed for 7/31 roof top delivery.

Excley parking lot D will be closed 7/31.

Second safety audit. Passed.

Dumpster abuse, different projects are using AZ's dumpster.

7/23

Old crac2 removed

New crac2 installed, planned startup Aug 14-16

Ductless AC piping ongoing

July 31st roof delivery, Lot D closure all work day

Consensus on cold air flow discharge (no changes)

Led lights being installed

Aug 12 containment measurements (vinyl curtain)

7/30

Crane arrives tomorrow, Thunderstorms expected

Excley lot closed 6am-5pm

Liebert missing components (gages, cables etc), resending

Equipment rails on roof ready

Ceiling work begun

Next week piping work for roof units

Aug 15th CRAC2 startup

Aug 16th modular wall up

July Photos

New plumbing and insulation

New plumbing and insulation

Related project, temp building UPS

Related project, temp building UPS

Ductless wall AC units

Ductless wall AC units

Ceiling grid

Ceiling grid

CRAC2 platform

CRAC2 platform

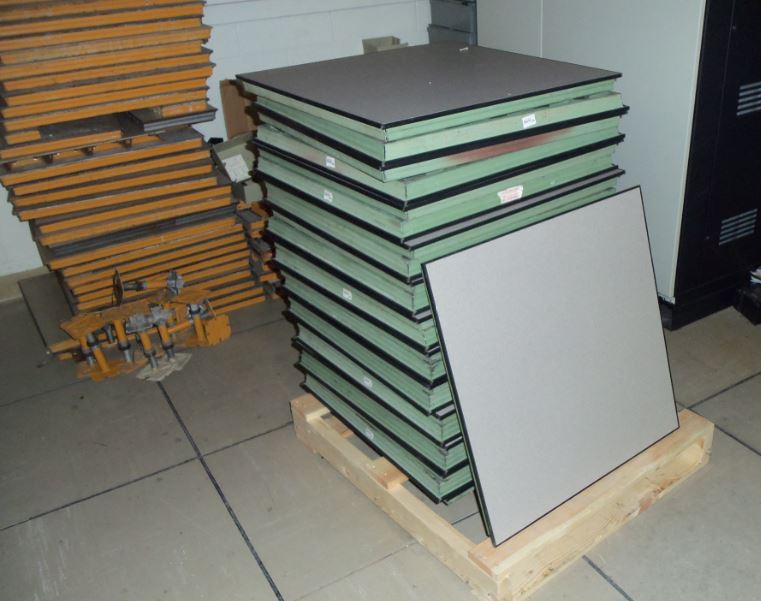

New floor tiles

New floor tiles

Old CRAC2 follows exit sign

Old CRAC2 follows exit sign

New CRAC2 arrival

New CRAC2 arrival

New CRAC2 placed

New CRAC2 placed

New LED lights and ceiling pads

New LED lights and ceiling pads

New piping, electric from roof

New piping, electric from roof

New piping for ductless AC units

New piping for ductless AC units

Roof exchanger for ductless AC units

Roof exchanger for ductless AC units

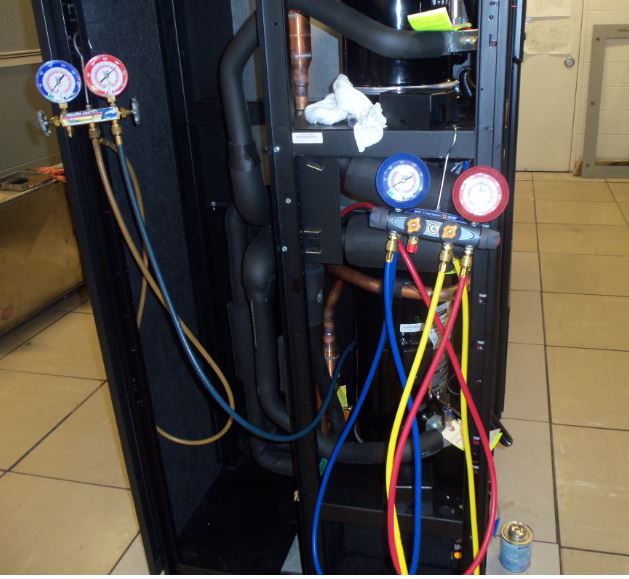

New CRAC2 unit innards

New CRAC2 unit innards

Roof equipment rails

Roof equipment rails

CRAC2 cold air fans, surprise location.

CRAC2 cold air fans, surprise location.

Crane day 7/31, thunderstorms expected

Crane day 7/31, thunderstorms expected

Assembly of roof chiller units

Assembly of roof chiller units

Economizers (box) and chillers on stilts

Economizers (box) and chillers on stilts

Aug Meetings

8/6

New Liebert components arrived (lost items to be returned if found)

Roof delivery items secured in place

New CRAC1 unit piping started from roof downwards

New CRAC1 unit location moved one foot forward based on floor plan

Utility power interrupt coming (panel across pleone's door inside DC)

Announcement coming (need to make sure we have win/unix/dbs on floor)

New CRAC2 startup 8/16 followed by demo old CRAC1

Floor closure in front of new CRAC2 (relocate fans?)

Open more floor near old CRAC1 to get more cold air from old CRAC3

Room/Racks temp monitor log started anticipating room air flow changes

8/13

Cancelled

8/20

Meetings moved to Thu afternoon (1pm now vs 7:30am)

New CRAC2 unit on, data center temp dropped 5-7 degrees

Modular wall up

Fire suppressant install next, followed by ceiling

Old CRAC1 demolishing started

08/22

Wall AC units on

Dim switch relocated, network area missing led installed

Old CRAC1 removed

Floor tiles slowly reconfigure, monitor temps

Condenser leak in second unit, new item shipped

Deliver new CRACR1 before move in day

Fire suppression wiring and piping today

Aug Photos

Crane rooftop delivery

Crane rooftop delivery

Drone rooftop side view

Drone rooftop side view

Drone rooftop top view

Drone rooftop top view

Odd location for dim switch

Odd location for dim switch

Novel use subfloor pedestal

Novel use subfloor pedestal

Out of service foam fire suppressant

Out of service foam fire suppressant

Do Not Operate, my life depends on it…

Do Not Operate, my life depends on it…

Transformer, new&old pipes, old mail tubes

Transformer, new&old pipes, old mail tubes

Hot gas (left, arrives), cold liquid (right, returns)

Hot gas (left, arrives), cold liquid (right, returns)

Hot gas in, cooled to Liquifier (black)

Hot gas in, cooled to Liquifier (black)

From Liquifier to Economizer

From Liquifier to Economizer

Charging, R-410A gas only, zeotropic mixture

Charging, R-410A gas only, zeotropic mixture

Seriously. Pink! Official industrial color

Seriously. Pink! Official industrial color

New Hall/Atwater-Excley generator (green one ;), 450 Kw, 16,000 lbs

New Hall/Atwater-Excley generator (green one ;), 450 Kw, 16,000 lbs

08/16/2019 New CRAC2

08/16/2019 New CRAC2

08/19/2019, Temp dropped 5-7F

08/19/2019, Temp dropped 5-7F

Modular wall up (back side)

Modular wall up (back side)

Front, wall edges will connect with vinyl curtains)

Front, wall edges will connect with vinyl curtains)

Cold aisle looking at CRAC2

Cold aisle looking at CRAC2

Old CRAC1 removed, new frame installed

Old CRAC1 removed, new frame installed

Sept Meetings

09/05

New electrician but critical work coming up

Missing one track sensor

CARC1 installed, piping finish and leak test

New CRAC1 power up 9/19 by Liebert with owner training

Duct work and dampers install today

09/19

Cancelled

Sept Photos

5-6 feet cold aisle

5-6 feet cold aisle

Tour Guide on back of modular wall

Tour Guide on back of modular wall

New CRAC1 pressurizing

New CRAC1 pressurizing

L-room return damper to hot aisle

L-room return damper to hot aisle

1of2 L-Room cold air supply damper

1of2 L-Room cold air supply damper

10/19 Startup delayed

10/19 Startup delayed

Cold aisle floor tile replacements

Cold aisle floor tile replacements

Old CRAC3 removed, 9/13/2019

Old CRAC3 removed, 9/13/2019

Circulation pumps inside Economizer

Circulation pumps inside Economizer

New wall paint job. Thanks!

New wall paint job. Thanks!

Zeocryte cylinder flock

Zeocryte cylinder flock

Old and new fans

Old and new fans

Vinyl doors and curtains, CRAC1 startup 10/10/2019

Vinyl doors and curtains, CRAC1 startup 10/10/2019

Top of racks vinyl curtain

Top of racks vinyl curtain

CRAC2 vinyl curtain and door

CRAC2 vinyl curtain and door

West hot aisle return to CRAC units

West hot aisle return to CRAC units

U42 rack is 78 3/4“ tall, door is 79”

U42 rack is 78 3/4“ tall, door is 79”